News

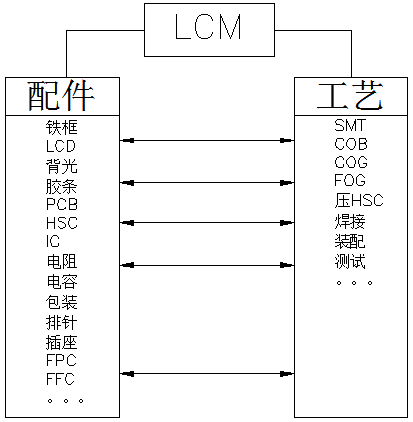

LCM: The Display Engine of Smart Devices - An In-depth Analysis of the Technical Core of LCD Modules

In modern electronic devices, the LCD screen serves as the medium for information presentation, and its performance directly impacts the user experience. However, the core technology that truly determines display quality and reliability is the LCM (LCD Module). This article provides an in-depth expl......

Read MoreFujian News Broadcast reports: CNK has become the best representative of Wuping's new display industry

Recently, Fujian TV News reported on the premiere of the large-scale media series "Chain Reaction Fujian: County Chiefs Speak," jointly launched by the Fujian Provincial Department of Industry and Information Technology and the Fujian Radio, Film, and Television Group. The first episode focused on W......

Read MoreIntelligence Integrates into Industry, Adding Momentum | CNK Electronics’ AI Pet Robot K-Baby Shines at Pingshan Innovation Exchange, Captivating the Audience!

November 19, 2025 – At the press conference hall on the first floor of the Yanzi Lake International Conference and Exhibition Center, the "AI Empowers Pingshan Innovation Exchange," themed "Intelligence Integrates into Industry Adding Momentum, AI Unites to Forge a New Chapter," was held as schedule......

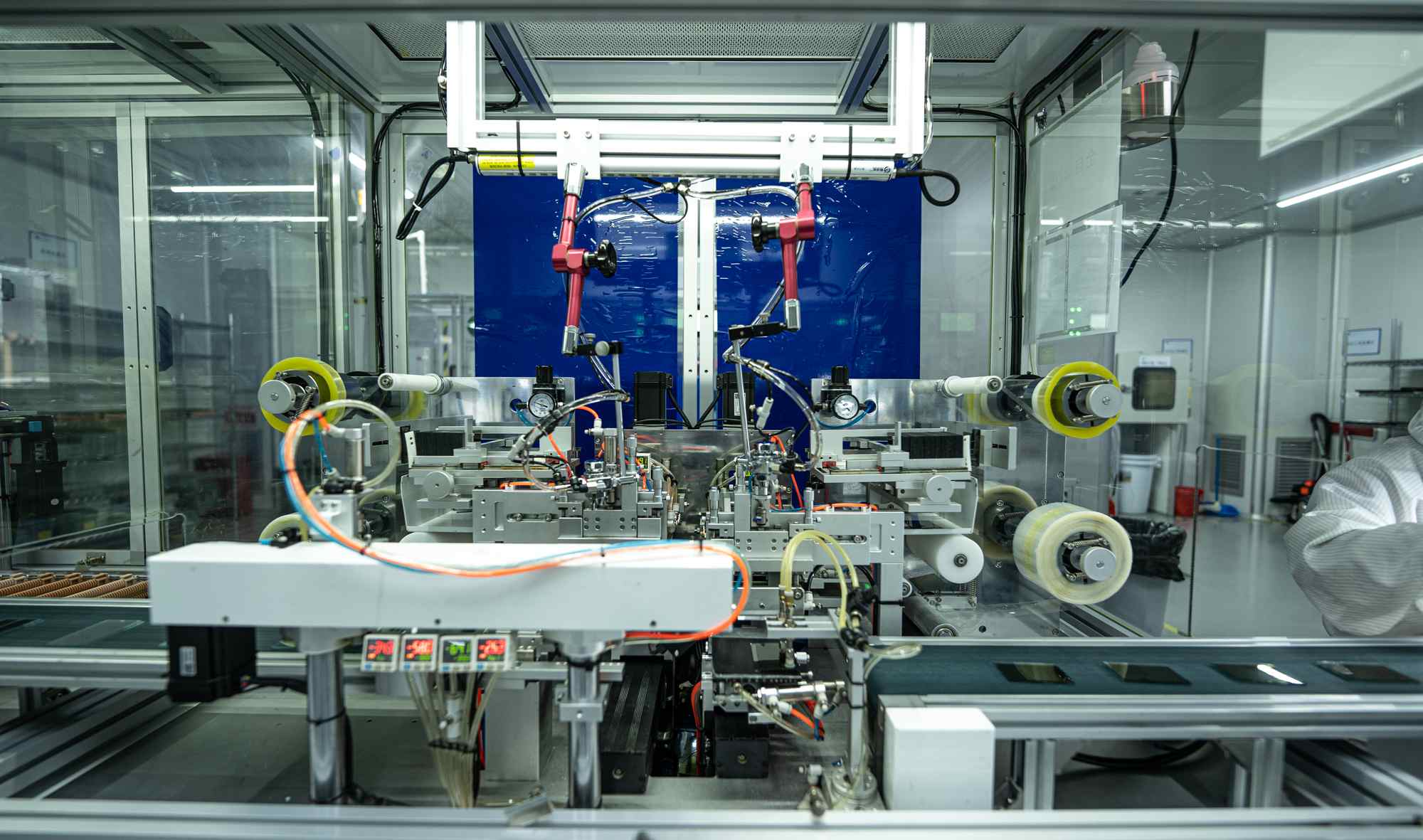

Read MorePrecision Alignment & Cell Assembly: Analyzing PI Coating and Rubbing Processes in LCD Manufacturing

The complete manufacturing process of LCD involves over 40 precise steps, which can be divided into five main stages: ITO pattern etching, alignment layer formation (PI coating and rubbing), cell assembly, liquid crystal filling and cutting, and final inspection and packaging. Among these, the PI co......

Read MoreITO Patterning: The Foundation of Precision LCD Manufacturing

Behind every clear and bright LCD screen lies a crucial precision process—ITO patterning. As the initial stage in the over 40 steps of LCD manufacturing, it is akin to "etching the negative" of the display world. Its accuracy directly determines the display quality and reliability of the LCD module.......

Read MoreAI Robotic Pet K-Bao: Redefining the Smart Companion Experience for Families

In today's rapidly evolving world of artificial intelligence, smart devices are increasingly integrating into our daily lives. We have launched a brand-new AI robot, the cute pet K Bao. With highly bionic design and multi-functional interaction at its core, it is committed to becoming an indispensab......

Read More