Precision Alignment & Cell Assembly: Analyzing PI Coating and Rubbing Processes in LCD Manufacturing

The complete manufacturing process of LCD involves over 40 precise steps, which can be divided into five main stages: ITO pattern etching, alignment layer formation (PI coating and rubbing), cell assembly, liquid crystal filling and cutting, and final inspection and packaging. Among these, the PI coating, alignment rubbing, and cell assembly processes serve as core components of the front-end, playing a decisive role in the manufacturing of LCD screens and directly influencing display performance.

PI Coating: Building the Foundation for Molecular Alignment

The application of the alignment layer onto the substrate surface is the first critical step in manufacturing LCD modules. Using precision selective coating technology, polyimide (PI) is uniformly applied to the ITO glass, followed by a strictly temperature-controlled curing process to form a stable alignment layer. Due to its excellent chemical stability, high insulation resistance, and high-temperature resistance, PI material ensures long-term reliability of the LCD screen. The precision of this process directly affects the alignment quality of the liquid crystal molecules in subsequent steps, forming the foundation for achieving high-performance display.

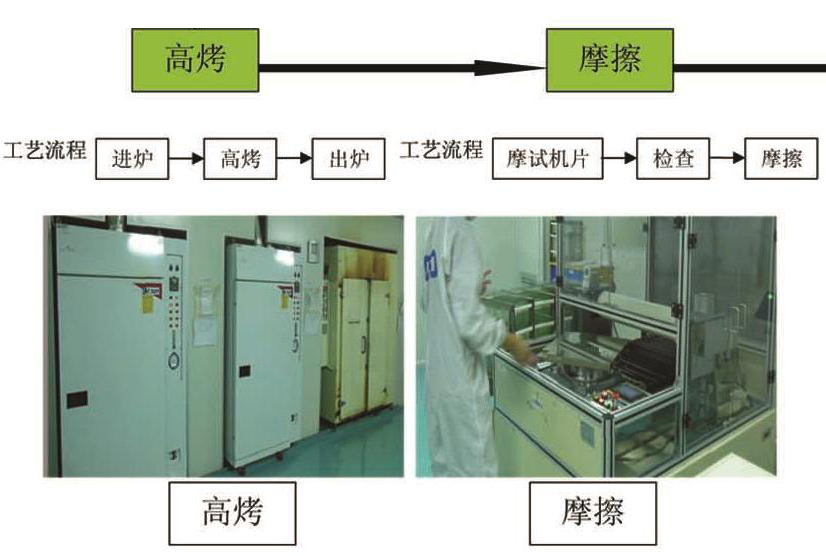

Alignment Rubbing: Precision Control of Microstructures

The alignment rubbing process involves using specialized velvet cloth to rub the PI layer surface in a specific direction, creating uniform microscopic grooves. These nano-scale grooves guide the liquid crystal molecules to align in a predetermined direction, thereby determining the viewing angle characteristics of the LCD screen. It is important to note that while the rubbing direction determines the viewing angle direction, it does not affect the viewing angle range. As professional LCD display manufacturers, we ensure that each customized LCD screen achieves the desired optical performance through precise control of rubbing angle and pressure.

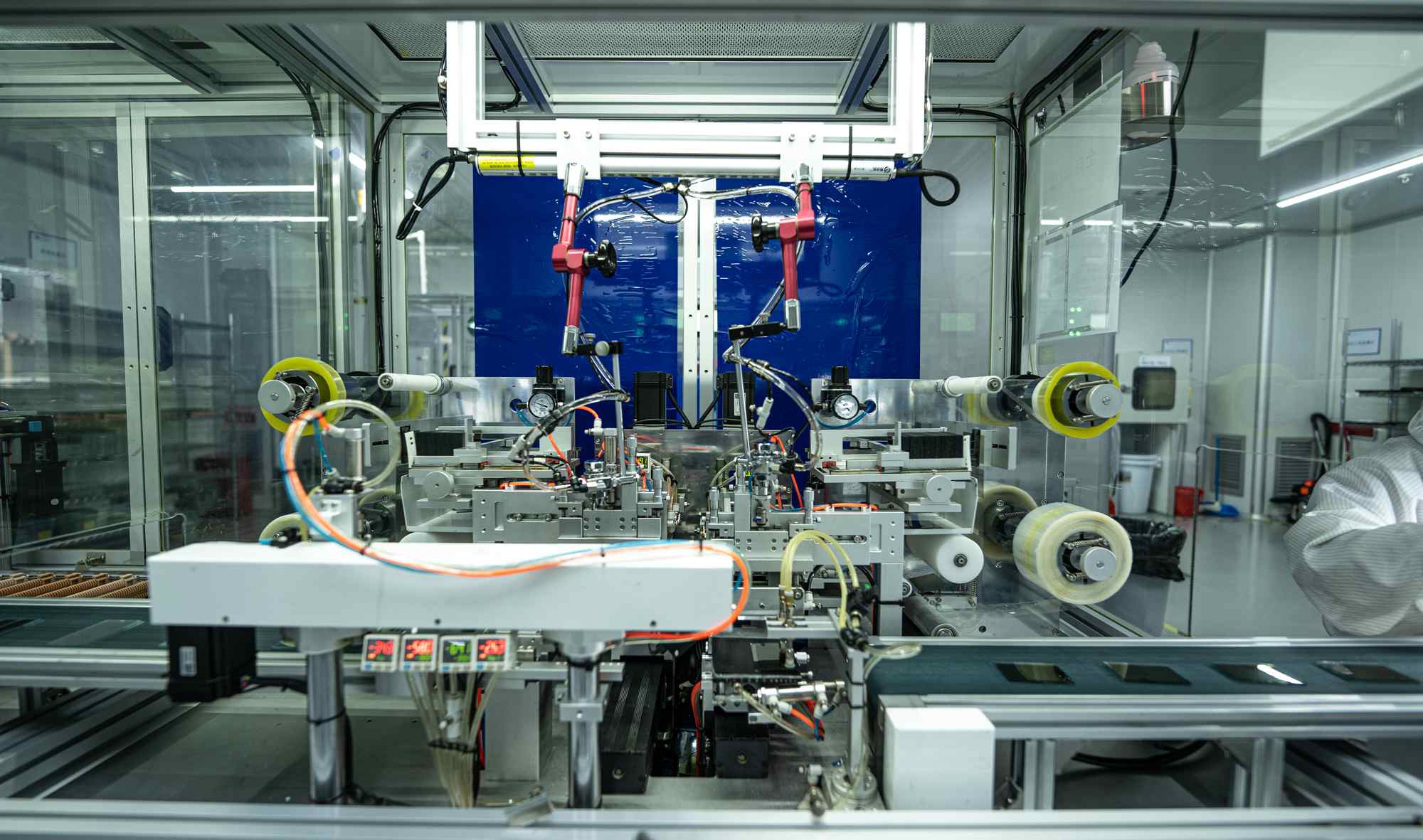

Cell Assembly: Constructing a Stable Display Unit

The cell assembly process involves three key steps:

Sealant Printing: Precise application of sealant using screen printing technology to form a sealed structure.

Spacer Spray: Uniform distribution of spacer materials to accurately control cell gap tolerance.

Assembly and Curing: Permanent bonding of upper and lower substrates through high-temperature curing.

This series of processes constructs a stable containment space for the liquid crystal molecules, where the machining accuracy directly affects the display uniformity and service life of the LCD module. Particularly in customized LCD screen production, we can adjust cell gap parameters according to customer requirements to optimize display performance.

Process Extension: The Special Value of TOP Coating

For high-end STN products, the TOP coating process adds an SiO2 layer after photolithography, which both fills electrode trenches and provides insulation and viewing angle improvement. This special process demonstrates LCD display manufacturers' continuous pursuit of product performance and provides more technical options for customized LCD screens.

Leveraging extensive expertise in PI coating, rubbing, and cell assembly processes, CNK Electronics ensures that each LCD module meets stringent quality standards. We are committed to providing reliable display solutions for global customers through precise process control and comprehensive quality systems, driving continuous advancement in display technology.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a national specialized and innovative "little giant" enterprise that specializes in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.