ITO Patterning: The Foundation of Precision LCD Manufacturing

Behind every clear and bright LCD screen lies a crucial precision process—ITO patterning. As the initial stage in the over 40 steps of LCD manufacturing, it is akin to "etching the negative" of the display world. Its accuracy directly determines the display quality and reliability of the LCD module. Whether for standard products or customized LCD screens, their unique display patterns originate from this process. This transformation of design blueprints into microscopic reality is a testament to the technical prowess of LCD display manufacturers.

ITO patterning transforms raw ITO glass into the desired electrode patterns through seven precise steps. This is not merely production but an art of "micro-engraving" at the micron level.

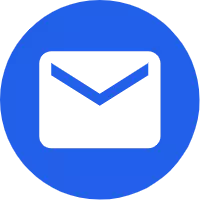

Step 1: Cleaning—A Pure Start

The ITO glass undergoes thorough cleaning with cleaning agents and deionized water to remove surface impurities. This seemingly simple step is the foundation for ensuring the quality of subsequent processes. Any minor flaw could affect the final display performance of the LCD screen.

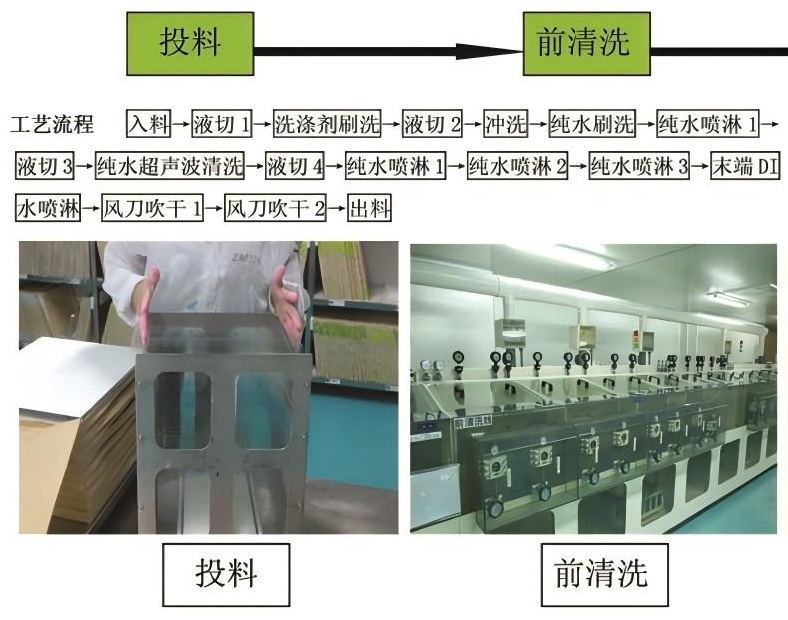

Step 2: Photoresist Coating—Uniform Coverage

A photoresist is evenly applied to the clean ITO conductive layer and baked. This thin photoresist layer acts as a temporary carrier for pattern transfer, and its uniformity directly impacts the precision of the subsequent patterns.

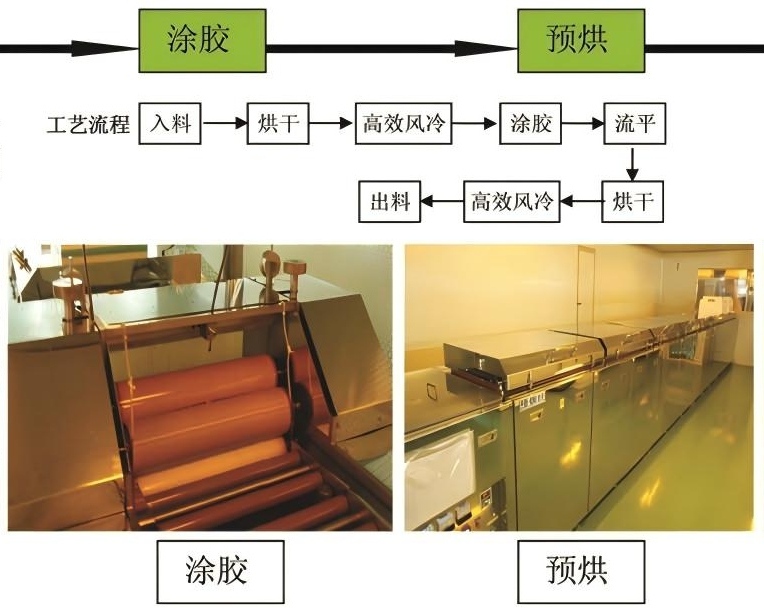

Step 3: Exposure—Defining with Light

The photoresist layer is exposed to ultraviolet light through a pre-made electrode pattern (photomask), causing a chemical reaction in the exposed areas. This process, much like developing a photographic negative, precisely defines the of every pixel on the future LCD screen.

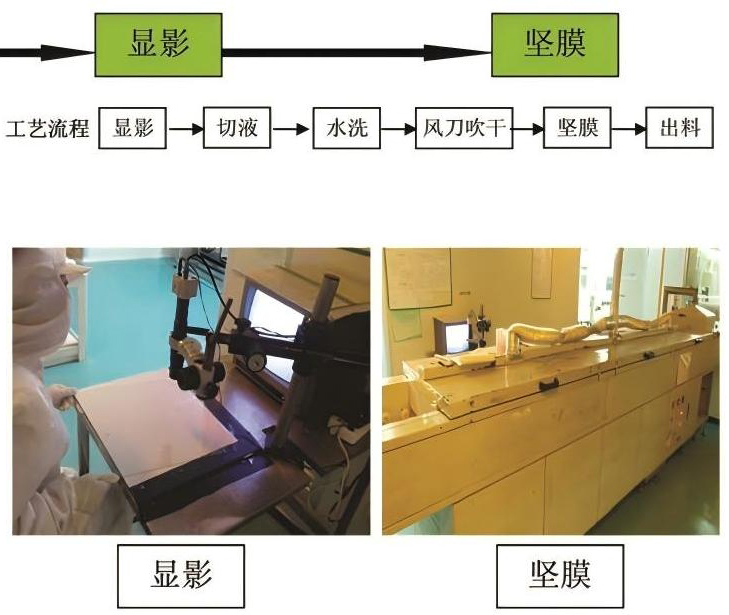

Step 4: Development—Pattern Emergence

The glass surface is treated with a developer to remove the exposed and decomposed photoresist. At this stage, the designed electrode pattern becomes visible for the first time in the form of the remaining photoresist, revealing the outlines of the pattern.

Step 5: Hard Baking—Reinforcement

The glass undergoes high-temperature treatment to strengthen the remaining photoresist layer. This step ensures the stability of the pattern barrier during the subsequent etching process and is critical for maintaining sharp pattern edges.

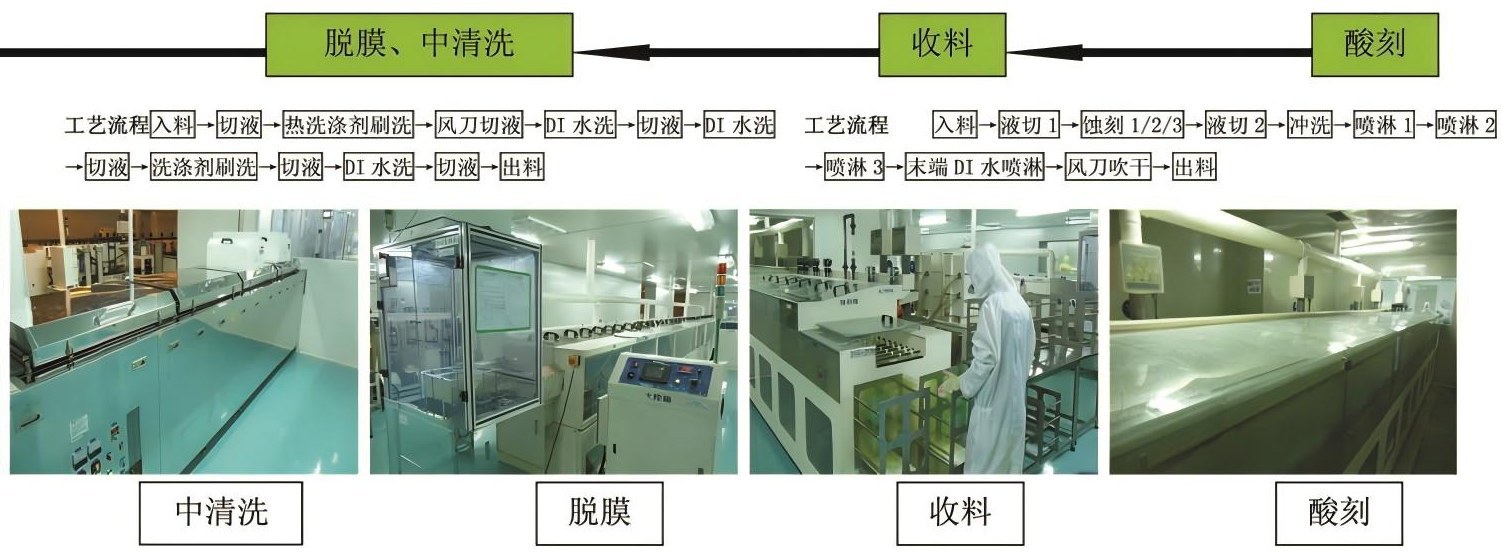

Step 6: Etching—Precision Engraving

An appropriate acid etching solution is used to corrode away the ITO film not covered by the photoresist. The protected areas remain intact, while the exposed areas are etched away, resulting in precise ITO electrode patterns.

Step 7: Stripping—Final Touches

A high-concentration alkaline solution is used to remove the remaining photoresist, leaving a pristine ITO pattern permanently on the glass substrate, exactly matching the design blueprint.

As a professional LCD display manufacturer, we recognize that every aspect of precision control, from the initial ITO pattern to the final LCD module, impacts the display quality of our customers' products. In custom LCD screen projects, we adjust various parameters of the pattern design according to specific customer requirements, ensuring that every LCD screen perfectly fits the needs of the end product. Choosing to collaborate with CNK means your display solution is professionally guaranteed from the most fundamental pattern stage. Let us work together to create a superior visual experience.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a national specialized and innovative "little giant" enterprise that specializes in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.