LCM: The Display Engine of Smart Devices - An In-depth Analysis of the Technical Core of LCD Modules

2025-12-01

In modern electronic devices, the LCD screen serves as the medium for information presentation, and its performance directly impacts the user experience. However, the core technology that truly determines display quality and reliability is the LCM (LCD Module). This article provides an in-depth exploration of the technical architecture of LCMs and their crucial role in the display field.

Technical Definition and Composition of LCM

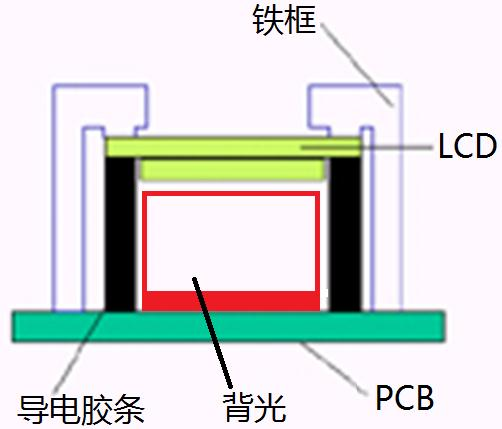

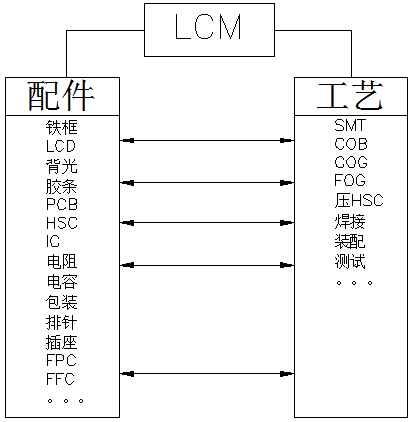

An LCM (LCD Module) is a highly integrated display solution that organically combines liquid crystal display devices, drive circuits, control chips, PCB substrates, backlight systems, and structural components. This integrated design not only simplifies the assembly process for OEMs but, more importantly, ensures optimal performance matching for the display system.

From a technical perspective, a standard LCM includes the following core components:

Display Core: LCD screen and drive chips

Circuit System: PCB board, resistors, capacitors, and other passive components

Connection System: FPC/FFC flexible circuits, pin headers, and sockets

Structural System: Metal frame, gaskets, backlight modules

Analysis of Core Manufacturing Processes

In the LCM manufacturing process, the combination of various specialized techniques ensures stable production:

SMT Process

Enables high-density component placement, ensuring precision and consistency in circuit connections. This is the fundamental process in modern electronics manufacturing, providing a stable circuit foundation for display driving.

COG Process

Directly bonds the drive IC onto the glass substrate. This process significantly reduces module size and improves connection reliability, making it suitable for applications with strict space requirements.

FOG Process

Achieves precise connection between flexible circuits and the glass substrate. This technology requires extremely high alignment accuracy to ensure stable signal transmission.

COB Process

Bonds ICs directly onto the PCB and protects them with resin sealing. This process enhances the module's mechanical strength and anti-interference capability.

Technical Analysis of Diversified Structural Solutions

As the core of the display system, the structural solution of an LCM directly determines its application field and performance:

Basic COG Solutions

LCD + COGIC: The most compact structural design

LCD + COGIC + PIN: Provides reliable pin connection

LCD + COGIC + FPC: Enables flexible circuit layout

LCD + COGIC + HSC: Enhances connector reliability

TAB Bonding Solution

Utilizes anisotropic conductive film to achieve connection between TCP and glass, providing excellent performance in specific applications.

COB Integration Solution

Bonds drive ICs directly onto the PCB, offering stronger environmental adaptability and mechanical stability for the module. Combined with touch functionality (LCD + COBIC + TK), it can meet the complex requirements of human-machine interaction applications.

Technical Considerations for Customized Development

In the development of custom LCD screens, multiple technical dimensions need comprehensive consideration:

Display performance parameters: Resolution, color depth, response time

Environmental adaptability: Operating temperature range, vibration resistance

Interface compatibility: Matching the signal requirements of the main control platform

Energy efficiency indicators: Meeting the power budget of end products

Through scientific system-level design, custom LCD screens can perfectly fit the technical requirements of specific application scenarios, providing differentiated display experiences for end products.

Technology Development Trends

With the continuous advancement of display technology, LCMs are evolving towards higher integration, lower power consumption, and stronger functionality. Emerging HMI human-machine interaction modules deeply integrate touch, display, and computing functions, bringing more intuitive interactive experiences to smart devices.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a national specialized and innovative "little giant" enterprise that specializes in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.