Optical Films in Backlight Modules: Key Technologies That Illuminate Every LCD Screen

2025-12-22

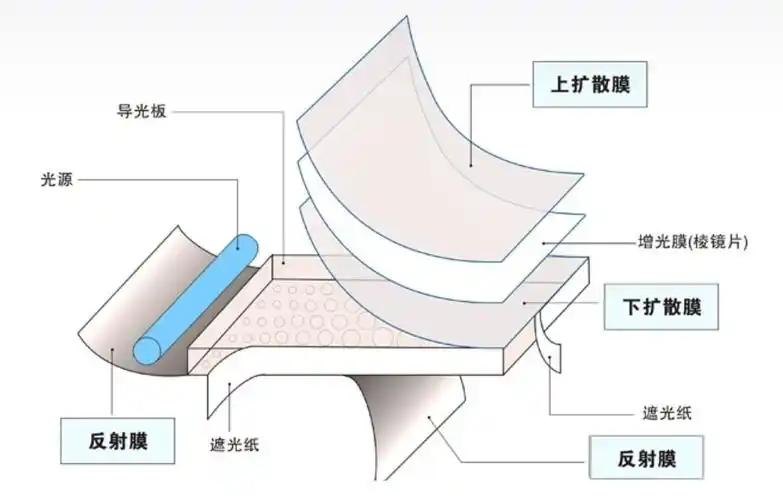

In the world of Liquid Crystal Displays (LCDs), the backlight module is one of the core components determining display performance. As an LCD display manufacturer, CNK Electronics Co., Ltd. understands that a backlight is not merely a light source component. It is a key technology that, through precise optical design, transforms point light sources into uniform, high-brightness, high-contrast surface illumination, thereby giving LCD screens their vivid visual life. Especially today, with the increasing market demand for customized LCDs, the optical performance of the backlight module has become a crucial factor in achieving differentiated display effects. This performance hinges largely on a series of precisely coordinated optical films within it. They function like the "neural network" of the backlight, meticulously controlling the direction, efficiency, and uniformity of light.

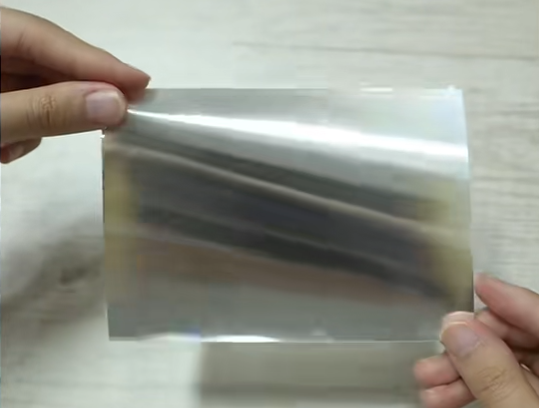

Reflector Sheet: The Foundation of Light Efficiency

At the bottom of the backlight module, the reflector sheet acts as the "foundation of light efficiency," responsible for redirecting stray light back into the light guide plate to improve utilization. Depending on application requirements, reflectors are mainly categorized as follows:

White Reflector: Such as the E20, RW series, with thickness ranging from 0.05~0.2mm, reflectivity around 80%~90%, and possessing certain light transmittance. Suitable for most standard backlight designs.

Silver Reflector: Typically white on one side and silver on the other, very thin (0.04~0.065mm), with high reflection efficiency (90%~98%) and excellent light-blocking properties. Often used in scenarios requiring high brightness.

Multilayer Film Reflector (ESR): Utilizes multilayer film technology, integrating over a thousand layers within 65 microns. It contains no metal yet has a mirror-like metallic appearance. As a high-efficiency reflector, ESR achieves a reflectivity of over 98% across the entire visible light spectrum, making it ideal for high-performance backlight systems.

When customizing LCD modules, the choice of reflector sheet directly impacts backlight uniformity and energy efficiency, representing the first step in optical design.

Light-Blocking Film / Aluminum Foil (ALF): Controlling Light and Interference Boundaries

Light-blocking films are primarily used to prevent light leakage from the sides of the backlight and can provide electromagnetic shielding. Common types include:

Bright Silver Dragon: Lustrous surface, thickness 0.05-0.1mm, good light-blocking properties and conductive. Suitable for industrial environments requiring interference shielding.

Matte Silver Dragon: Relatively dull finish, thin (typically 0.05mm for single layer), possesses some light transmittance and is conductive.

White Edge Strip: Possesses certain light transmittance, thickness 0.05-0.08mm, non-conductive. Commonly used in general consumer electronics.

Black & White Single-Sided Adhesive Tape: Can be applied to the sides of the backlight when there are strict requirements for non-conductivity and no side light leakage.

These materials play the role of "optical guardians" in the bezel design of LCD screens, ensuring no stray light interference outside the display area.

Diffuser Sheet: Creating a Uniform Light Canvas

As the "homogenizing master" among optical films, the diffuser sheet scatters light through haze, eliminating traces of point light sources to create soft and uniform backlight output. Depending on backlight type and application, diffusers are divided into:

Bottom Backlight Diffuser: Usually has adhesive on one side, high haze (~90%), transmittance only about 40%; thickness typically between 0.18~0.3mm for bottom backlights. Common models: MB433P, MB533.

Side Backlight Diffuser: Commonly used thickness is 0.09mm. Common models: TPRA90 (0.09mm), AJ-75 (0.075mm). Transmittance 65%-80%, haze 75%-90%.

Color Screen Backlight Diffusers: Typically use a two-sheet design:

Bottom Diffuser: Placed between the light guide plate and brightness enhancement film (BEF), homogenizes light emitted from the light guide plate. Commonly used material: t=0.065mm, relatively high haze (~84%), high transmittance (~98%).

Top Diffuser: Placed above the BEF, serves a protective role and helps prevent moiré patterns. Commonly used material: t=0.05mm, relatively low haze (~29%), transmittance 90%.

The proper selection and combination of diffuser sheets are key to ensuring uniform, spot-free display in LCD modules.

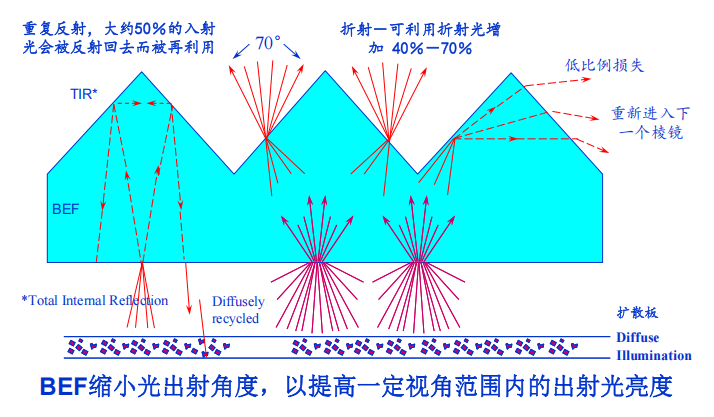

Brightness Enhancement Film (BEF): The Optical Engine for Boosting Brightness

For color TFT and other LCD screens, brightness is a critical specification. Acting as the "brightness amplifier" among optical films, the BEF concentrates scattered light through a special prism structure, with each film providing approximately 40%-50% brightness gain. Using two films in combination can multiply the brightness. Its principle involves using a micro-prism array to control the light path, causing most light to exit perpendicular to the screen, thereby significantly increasing frontal brightness without changing energy consumption. BEF has become an indispensable component in mid-to-high-end color screen backlights, especially widely used in high-performance customized LCDs for industrial control, medical, automotive, and other applications.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a national specialized and innovative "little giant" enterprise that specializes in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.