Decoding Precision Optics: The Core of Custom LCD Screens - Light Source and Light Guide Plate Technology

2025-12-19

In the professional display field, when you choose to customize an LCD screen, the exceptional visual performance behind it relies on the precise collaboration of two core optical components: the light source and the light guide plate. As an experienced LCD display manufacturer, CNK Electronics deeply understands that the brightness uniformity, color fidelity, and structural reliability of an excellent LCD module all depend on a profound understanding and precise control of these fundamental elements.

I. Light Source: The Precise Engine of Color and Brightness

The light source is the origin of display performance. Its technical parameters directly define the visual foundation of the LCD screen.

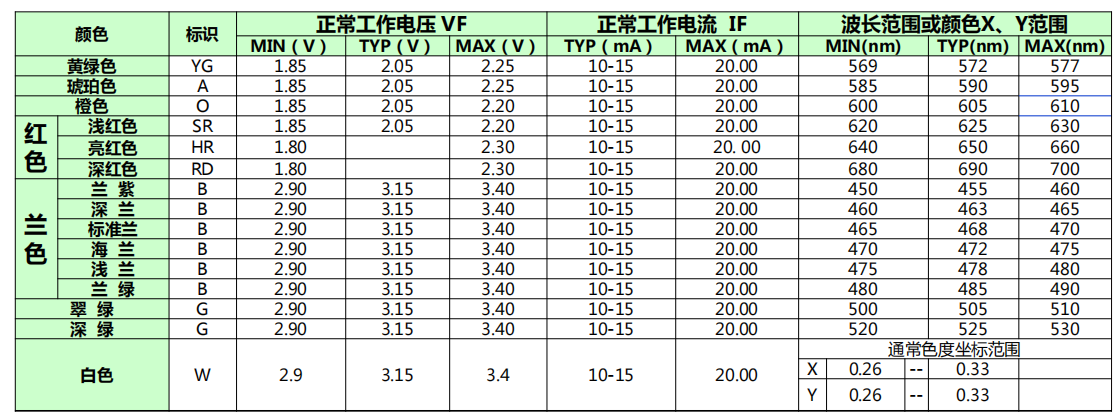

Precise Definition of Color Temperature: The chromaticity coordinates of the light source precisely control the display hue. 0.25-0.29 indicates cool white, 0.29-0.32 indicates pure white, and 0.32-0.35 indicates warm white. Professional LCD display manufacturers match the optimal color temperature for different LCD screen types (e.g., STN, VA) to enhance the visual experience. In customize LCD services, we can strictly control batch-to-batch variation of white color coordinates within △X=△Y ≤ 0.04.

Consistency Guarantee for Brightness: We ensure high brightness uniformity within the same batch of LCD modules, with inter-batch brightness stability maintained within 75%-140% of the specification value, providing reliable assurance for volume applications.

Scientific Matching of Optical Structure: For different structures like bottom backlight and side backlight, we scientifically select LEDs with different viewing angles (e.g., 96° or 120°). This is key to achieving ultra-thin designs or specific optical performances, and a core consideration in the structural assessment for customize LCD screens.

II. Light Guide Plate: The Precision Component for Achieving Uniform Light Emission

The light guide plate is responsible for transforming point light sources into a uniform surface light source. Its design and material are critical to optical performance.

Material Science: The Precise Choice between PMMA and PC

PMMA (Acrylic): Offers excellent light transmittance, suitable for most commercial products at room temperature.

Transparent PC Material: Such as PC1250Y, with its high strength, high-temperature resistance, and excellent flexibility, is the preferred choice for customize LCD screens used in wide-temperature or complex-structure applications like industrial and automotive displays. A simple identification method: PC material can be shaved into extending strips, while PMMA is brittle and breaks easily.

Dot Pattern Design: The Microscopic Secret to Optical Uniformity

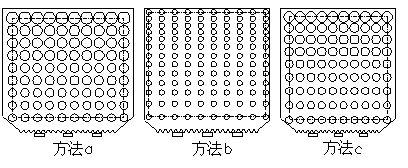

The precision dot pattern on the bottom surface of the light guide plate is the core technology for disrupting total internal reflection and achieving uniform light emission. Among these, circular dot pattern design is the most widely used and reliable solution, primarily involving three scientific methods:

Method A (Constant Pitch, Variable Dot Size): The distance between dot centers remains constant. Starting from the LED side, the diameter of the dots gradually increases. This method is relatively straightforward in design.

Method B (Constant Dot Size, Variable Pitch): The diameter of the dots remains constant. Starting from the LED side, the distribution spacing between dots gradually decreases, making the pattern denser.

Method C (Variable Dot Size and Variable Pitch): Starting from the LED side, both the diameter of the dots and the distribution spacing gradually decrease. This scheme allows for more refined and gradual guidance of the light path, typically resulting in superior uniformity compared to the first two single-variable methods, representing a higher level of design expertise.

III. Professional Manufacturing, Enabling Precision Optical Display

From the precise control of the light source spectrum to the scientific selection of light guide plate materials and the micron-level design of the dot pattern structure (especially the variable size and pitch scheme pursuing ultimate uniformity), each step reflects a deep understanding of optical physics and precise mastery of manufacturing processes. CNK Electronics deeply integrates these core optical device technologies to provide customers with comprehensive solutions, from standard products to deeply customize LCD screens.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a national specialized and innovative "little giant" enterprise that specializes in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.