Polarizers: The "Optical Gatekeepers" of LCD Screens

When you admire the vibrant images on an LCD screen, a seemingly ordinary thin film plays a critical, yet often unseen, role—the polarizer. This sophisticated optical component acts as a precise "gatekeeper," meticulously controlling the entry and exit of light, making it indispensable for Liquid Crystal Display (LCD) technology.

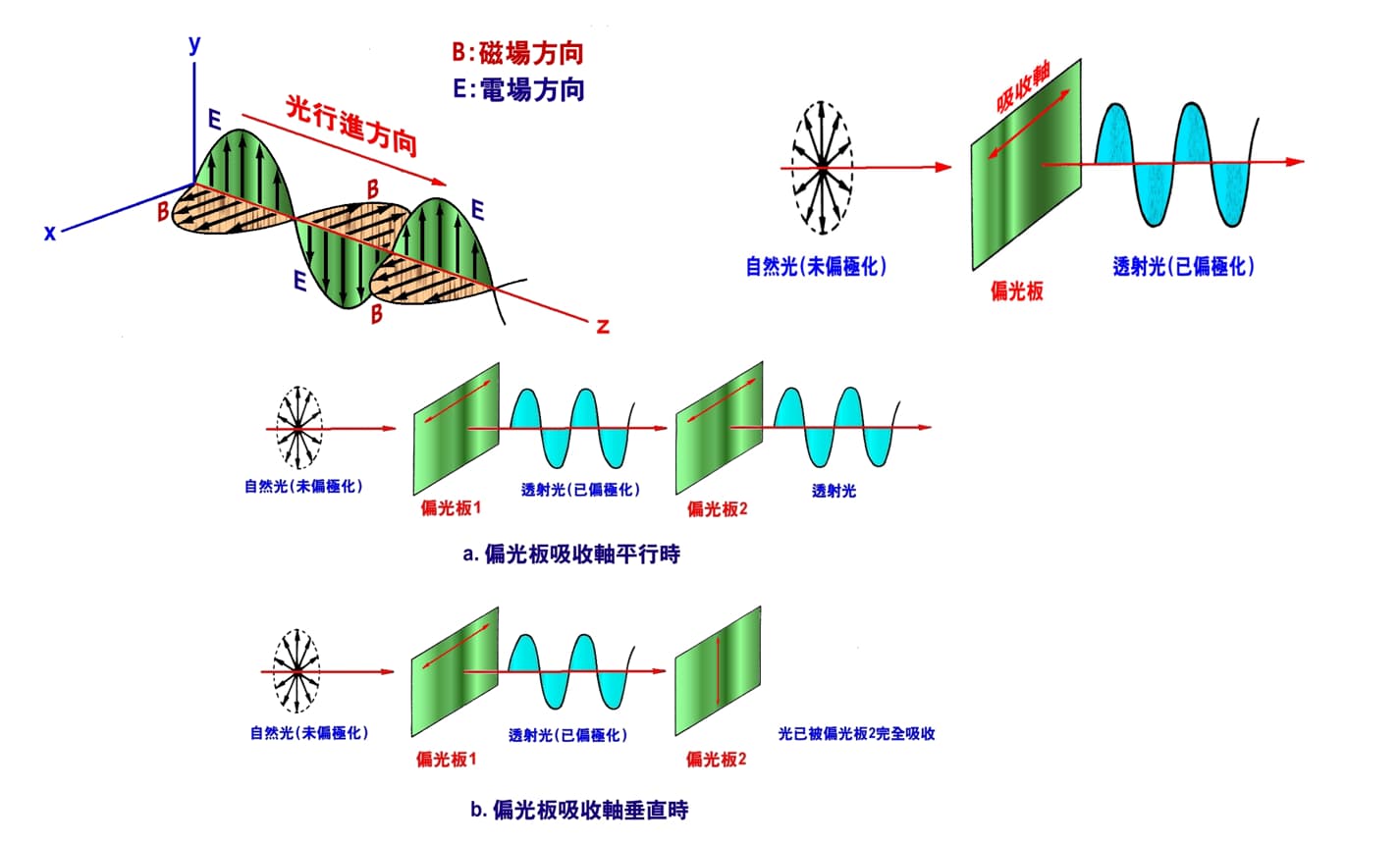

The Bidirectional Light Gate

LCDs rely on backlight units for illumination. The core function of the polarizer is twofold:

Input Filtering (Bottom Polarizer): Converts the chaotic, unpolarized natural light from the backlight into polarized light with a uniform vibration direction.

Output Control (Top Polarizer): Oriented typically 90 degrees perpendicular to the bottom polarizer. Light can only pass through if the liquid crystal molecules successfully rotate the polarization direction to match the "pass condition" of the top polarizer, creating the light/dark patterns that form the visible image.

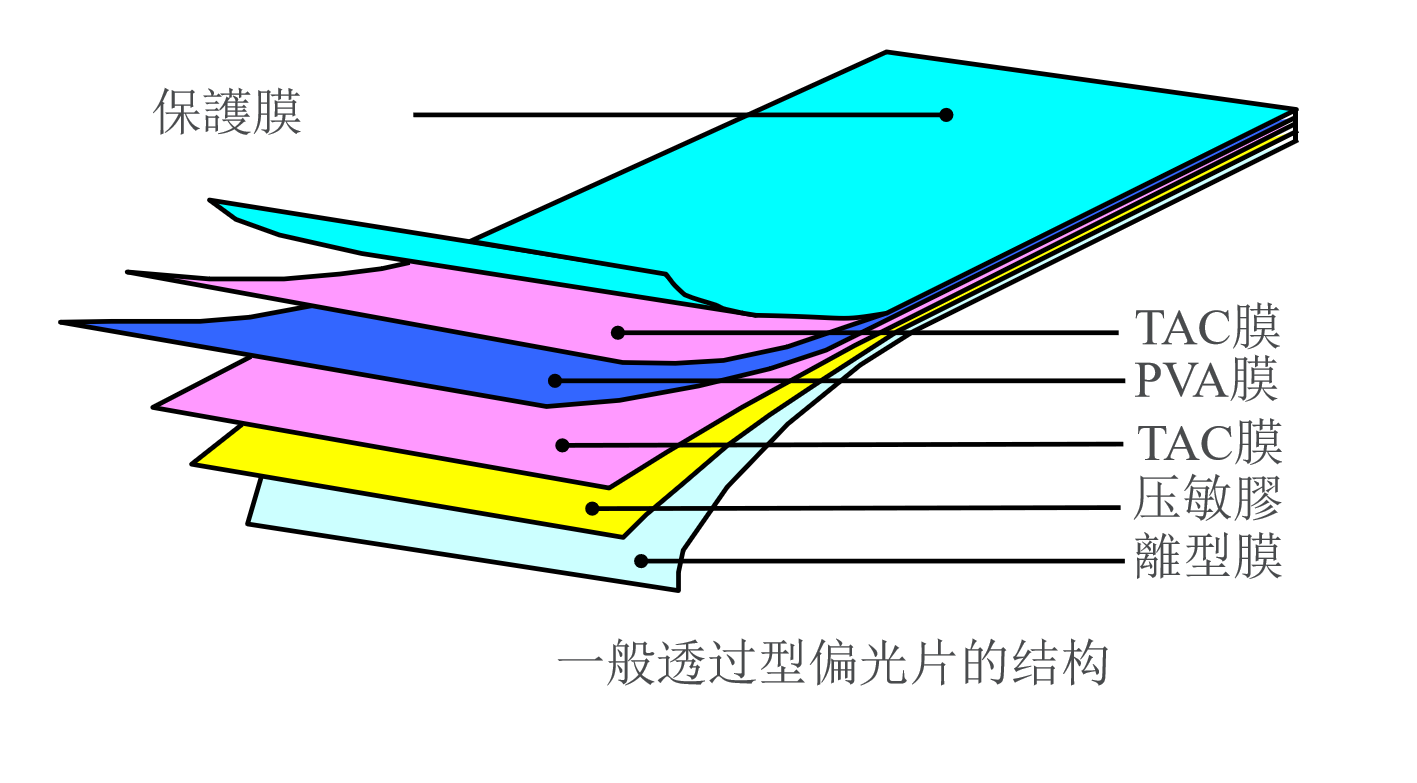

The Precision Five-Layer "Sandwich" Structure

A polarizer is a precisely engineered composite of five functional layers:

TAC Film (Triacetyl Cellulose - Top & Bottom Layers): Acts as a "robust shield" and "optical compensator." Provides physical protection (scratch, moisture resistance) and compensates for optical distortion due to its low optical retardation property, ensuring color purity and minimal image distortion.

PVA Film (Polyvinyl Alcohol - Core Layer): The "polarized light generator." Through stretching and dyeing (iodine or dichroic), its molecular chains become aligned, exhibiting strong dichroism – absorbing light waves of one vibration direction while transmitting those perpendicular to it, efficiently generating polarized light. Its performance defines the polarizer's efficiency (polarization degree) and transmittance.

Pressure Sensitive Adhesive (PSA): The "invisible bonding agent." Securely and uniformly laminates the polarizer assembly onto the liquid crystal glass cell substrate. Requires high transparency, long-term stability, weather resistance, non-corrosiveness, and minimal bubble/defect formation.

Release Film: The "transportation protector." Shields the PSA layer from contamination and accidental adhesion during production, shipping, and storage. It is peeled off and discarded just before the lamination process in the panel factory.

Continuous Evolution for Future Demands

The pursuit of higher image quality (4K/8K, HDR), wider viewing angles, thinner profiles, and flexibility drives continuous innovation in polarizer technology:

Thinner Profiles: Adoption of thinner TAC or alternative materials like COP (Cyclo Olefin Polymer) or PET films.

Enhanced Performance: Optimization of PVA processing to increase transmittance and contrast ratio.

Wider Viewing Angles: Integration of optical compensation films to mitigate inherent LCD viewing angle limitations.

Flexibility: Development of flexible polarizers compatible with foldable displays and flexible OLEDs.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a specialized and innovative enterprise specializing in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.