The Art of Precision Display: Decoding the Core Technical Parameters of LCD Screens

In today's era of rapid smart device development, the LCD Screen serves as the core interface for human-computer interaction, and its performance directly determines the quality of the user experience. Whether in consumer electronics or industrial control, demands on display performance are increasingly stringent. As professional LCD display manufacturers, we deeply understand that a thorough comprehension of LCD technology is the foundation for making correct choices and designs. This article will systematically analyze the key technical indicators that determine the quality of an LCD module.

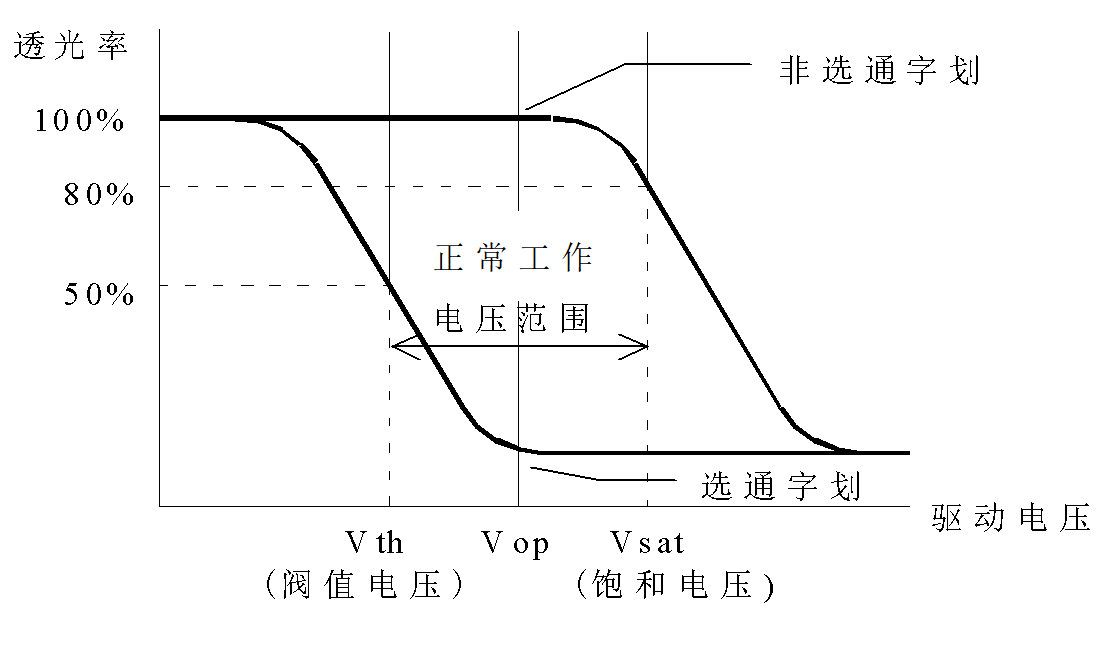

1. Electro-Optic Response Characteristic: The Physical Foundation of Display Control

The electro-optic response characteristic is the physical core of liquid crystal display technology. It precisely describes the functional relationship between the transmittance of an LCD screen and the applied driving voltage. This non-linear characteristic curve is the basis for achieving grayscale levels and image display. A well-optimized electro-optic response means lower driving voltage, higher contrast ratio, and more accurate color reproduction—it is the starting point for all high-end display designs.

2. Contrast Ratio: The Primary Element of Visual Clarity

Contrast ratio, defined as the ratio of luminance between the ON (active) state and the OFF (inactive) state, is the primary parameter for judging image sharpness and depth. Typically, when the contrast ratio exceeds 5:1, the human eye perceives a clear image. However, the contrast ratio of an LCD is a dynamic variable; it depends heavily on the viewing angle and ambient light, which leads to the next key metric—viewing angle characteristics.

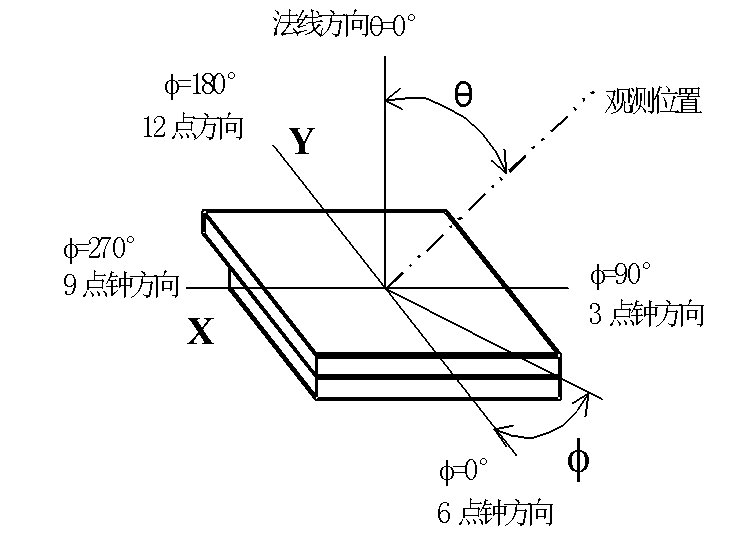

3. Viewing Angle Range: The Precise Synergy of Molecular Alignment and Optics

The viewing angle range is a comprehensive indicator that assesses an LCD module's ability to maintain display quality when viewed off-axis. It is not a fixed value but is defined by the spatial cone angle within which the contrast ratio decays to an acceptable lower limit (e.g., 5:1). Its essence lies in the complex interaction between the orientation of the liquid crystal molecules and the polarization state of the incident light.

Technical Depth:

Mode Determines Boundaries: Different liquid crystal modes (TN, HTN, STN) are fundamentally different designs of molecular alignment and twist angle. TN mode has the narrowest viewing angle, while STN mode, through high twist angles of 180°-270°, achieves a steeper electro-optic curve and a wider viewing angle. For instance, STN positive mode can maintain excellent visibility across a nearly hemispherical range, a key reason for its prevalence in industrial instruments and public displays.

Constraint of Driver Lines (Multiplexing): In LCD screens using multiplexed driving, as the number of driver lines (COM lines) increases, the effective voltage ratio applied to pixels deteriorates. This electrical non-ideality directly leads to a shrinkage in viewing angle performance. Therefore, for high-resolution character segment screens, the viewing angle often becomes a key trade-off with the driving scheme.

For applications with fixed viewing angle requirements, a customized LCD screen offers the optimal solution. Professional LCD display manufacturers can "steer" the optimal viewing angle towards the target observation area by adjusting parameters such as the alignment layer direction and optimizing the cell gap and birefringence product (Δn·d), thereby maximizing the utilization of display resources.

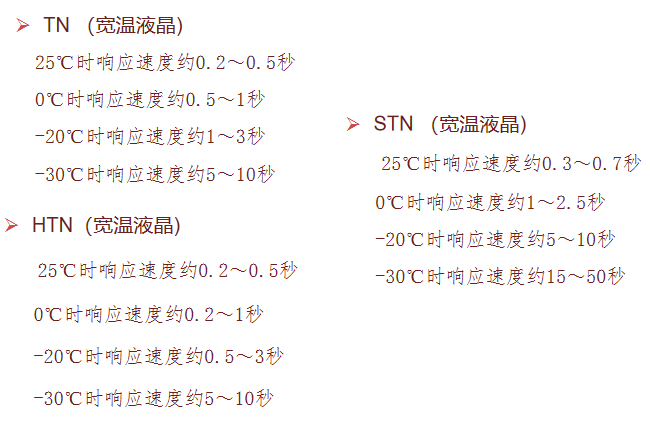

4. Response Speed: The Temperature Dependence of Dynamic Response

Response speed, including rise time (Tr) and fall time (Tf), measures how quickly an LCD screen responds to signals. The rheological properties of liquid crystals determine their strong temperature dependence: the lower the temperature, the higher the liquid crystal viscosity, and the slower the response speed.

Room Temperature Performance: At 25°C, the response time of TN/HTN products is typically in the range of 150-300 milliseconds, while STN products, due to their larger molecular twist angles, are slightly slower, around 200-350 milliseconds. This is sufficient for most static or slow-refresh display needs.

Wide-Temperature Challenge: In wide-temperature application scenarios, the response delay at low temperatures cannot be ignored. For example, a wide-temperature TN LCD module might have a response time of up to 10 seconds at -30°C, causing severe image smearing. This requires LCD display manufacturers to carefully select liquid crystal materials and adjust driving parameters for the target operating temperature range to ensure usable response performance even under extreme conditions.

5. Power Consumption: The Philosophy of Microamp-Level System Efficiency

Low power consumption is the cornerstone of LCD technology's dominance in the portable device market. The total power consumption of an LCD module is primarily composed of the capacitive charging/discharging of the drive circuit and the dielectric loss of the liquid crystal material. Among these, the bulk resistivity of the liquid crystal material itself is key to maintaining ultra-low static power consumption. If the material becomes contaminated, causing a drop in resistivity, power consumption can spike abnormally. Therefore, excellent power consumption control reflects the LCD display manufacturers' extreme control over material purity and production processes, ensuring that the LCD screen you receive maintains the advantage of microamp-level power consumption stably throughout its entire lifecycle.

Conclusion

In the current landscape where standard products often fail to perfectly meet specific requirements, customized LCD screens have become key to achieving product differentiation. By collaborating with technically profound LCD display manufacturers to deeply couple the core technical parameters mentioned above with your application scenario, you can develop an LCD module that finds the optimal balance between viewing angle, power consumption, temperature performance, and cost, ultimately delivering a flawless visual experience in your product.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a specialized and innovative enterprise specializing in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.