Decoding LCD Core Technology: From Basic Structure to Customized Solutions

2025-11-07

In today's era of intelligent and digital transformation, LCD screens serve as core components of human-machine interaction, widely used in industrial control, medical equipment, consumer electronics, and other fields. This article will take you deep into exploring the basic structure, key materials, and technical characteristics of LCDs, while demonstrating how customized LCD screens can meet diverse application requirements.

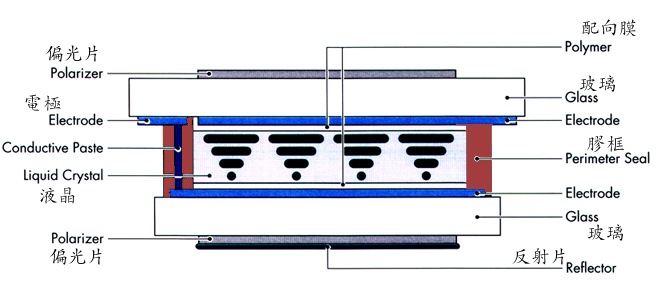

I. Basic Structure of LCD Displays

The core structure of LCDs consists of multiple precisely laminated materials, including polarizers, electrodes, conductive paste, liquid crystal, alignment films, glass substrates, perimeter seals, and reflectors. Each material layer serves unique functions:

Polarizers control the polarization direction of light;

Electrodes drive liquid crystal molecules to rotate by applying voltage;

Liquid Crystal acts as the electro-optical response medium, key to image display;

Glass Substrates not only provide support but also carry ITO conductive layers.

This multi-layer structure ensures that LCDs achieve high contrast and stable display with low power consumption, laying a solid foundation for various LCD modules.

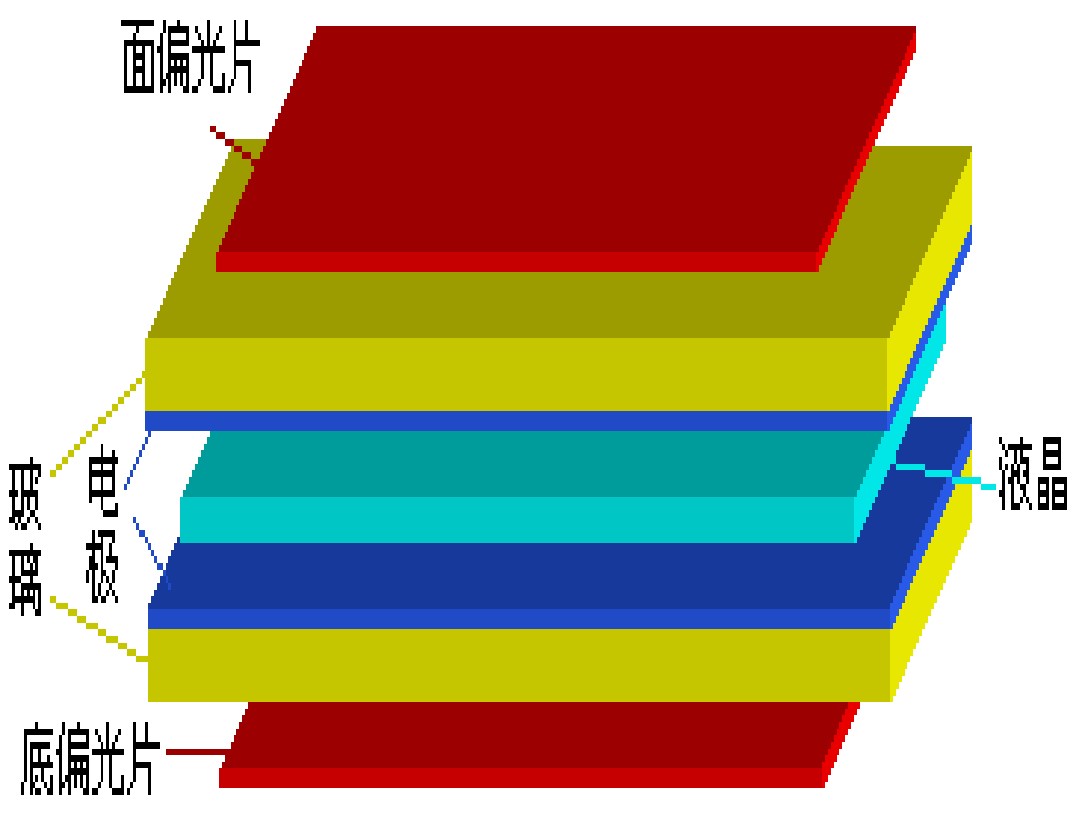

II. Material Differences in TN, HTN, and STN LCD Displays

Based on different arrangements of liquid crystal molecules, LCDs can be categorized into TN, HTN, and STN types. Their core materials include top polarizers, glass, electrodes, liquid crystal, and bottom polarizers. For example, STN displays significantly improve viewing angles and contrast by optimizing the twist angle of liquid crystal molecules, making them suitable for high-information-content display scenarios. Professional LCD display manufacturers ensure optimal response speed, viewing angles, and reliability for each LCD screen by flexibly adjusting material combinations.

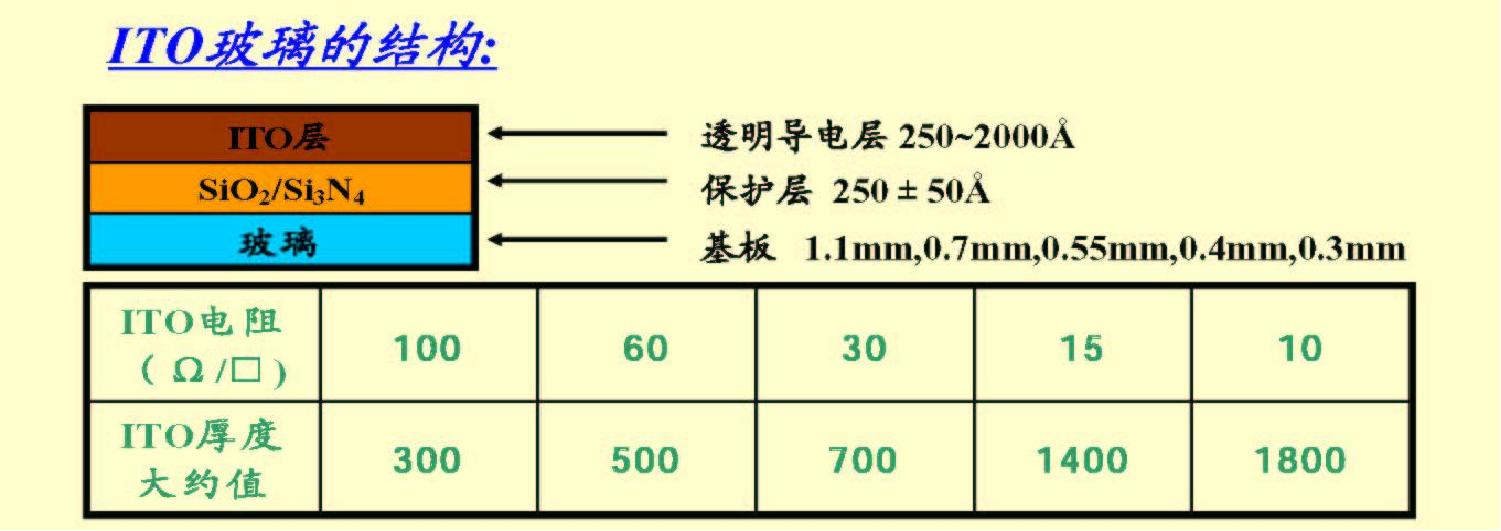

III. Key Materials: ITO Glass and Polarizers

ITO Glass: As the transparent conductive substrate for LCDs, the thickness of the ITO layer is directly related to its resistance value. For instance, when the ITO resistance is 10Ω, the thickness can reach 1800Å. Additionally, SiO2 or Si3N4 protective layers effectively prevent ion penetration, extending the service life of LCD modules. The use of borosilicate glass substrates meets ultra-thin and high-durability display requirements by enhancing light transmittance and hardness.

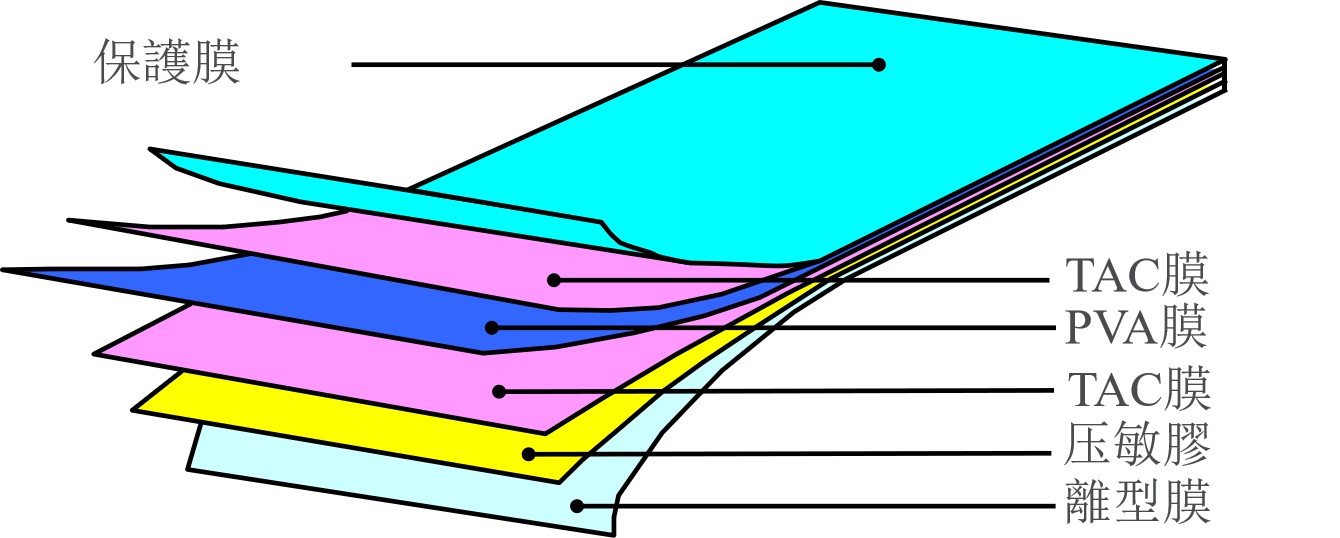

Polarizers: Their structure includes protective films, TAC films, PVA films, pressure-sensitive adhesives, and release films. The durability of polarizers directly affects LCD reliability. The industry offers multiple durability rating options:

Standard grade: Dry heat resistance 70°C×500HR, Damp heat 40℃, 90%RH, 500H

High durability grade: Dry heat resistance 90°C×500HR, Damp heat 80℃, 90%RH, 500H

This material advantage enables customized LCD screens to operate stably even in extreme environments, suitable for applications such as industrial control and outdoor equipment.

IV. Customized Solutions: Meeting Diverse Application Needs

By adjusting ITO glass resistance, polarizer durability, and liquid crystal types, fully customized LCD screens and LCD modules can be provided to customers. Whether high-resolution TFT modules or low-power OLED solutions, precise matching can be achieved to help customers enhance product competitiveness.

Conclusion

LCD technology continues to drive innovation in the display industry with its mature, stable, and customizable characteristics. As a professional LCD display manufacturer, CNK Electronics deeply understands material structures and processes, committed to providing global customers with high-quality LCD modules and customized LCD screens. If you are looking for reliable display solutions, please feel free to contact us - let us create excellent display experiences for you with our professional expertise!

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a specialized and innovative enterprise specializing in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.