How to Select and Customize the Optimal LCM Solution for Your Smart Device

During the initial stages of smart hardware design, one of the core challenges engineers face is selecting a "bright and clear eye" for the product – the Liquid Crystal Display Module (LCM). As a professional lcd display manufacturer, CNK Electronics understands that an excellent LCM solution involves far more than just choosing an lcd screen. It encompasses precision structures, diverse display technologies, and seamless integration with the whole device. Today, we will share insights from a technical perspective on how to tailor the most suitable lcd module for your needs.Part One: Structural Selection – The Foundation Determining LCM Reliability and Integration Level

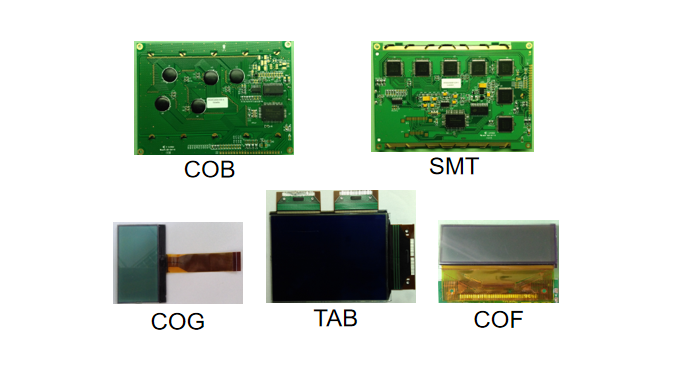

The core foundation of an LCM lies in its internal structure, which directly impacts product reliability, thickness, and cost. We primarily offer two technological paths: COB and COG.

COB Structure: Suitable for scenarios requiring high structural strength. Its characteristic is that the IC is bonded onto the PCB, achieved via SMT or bonding processes. The structure is robust and can be optionally paired with a metal frame for enhanced compression resistance. This structure primarily supports ITO glass thicknesses of 1.1mm and 0.7mm, making it a sturdy choice for fields like industrial control and home appliances.

COG Structure: This is the key technology for achieving ultra-thin profiles and high pixel density. The IC is bonded directly onto the ITO glass of the lcd screen, eliminating the need for an additional PCB and significantly reducing the module volume. It supports a wider range of ITO thicknesses, from 1.1mm down to 0.4mm. Particularly, the 0.4mm and 0.55mm thin glass types can meet the extreme thinness requirements of wearable devices and high-end portable instruments.

Furthermore, the connection method is equally crucial. From traditional zebra strip/elastomer connections to more advanced FPC, TAB, and COF connections, we can select the optimal electrical connection solution when you customize lcd screen components, based on your signal transmission requirements and spatial layout.

Part Two: Display Technology – Precisely Matching Visual and Power Requirements

After selecting the structure, the choice of display technology determines the final visual performance. Different types of lcd screen offer varying contrast ratios, viewing angles, and response speeds.

Basic to Mid/High-End Options: For cost-sensitive applications with lower display requirements, TN/HTN are economical choices. When higher contrast ratios and wider viewing angles are needed, the STN series (STN-YG/BLUE/GRAY) and their upgraded versions like ASTN/FSTN provide excellent monochrome display performance. It is worth noting that FSTN and DFSTN can achieve display quality comparable to TFT screens, making them the preferred choice for many high-end instruments.

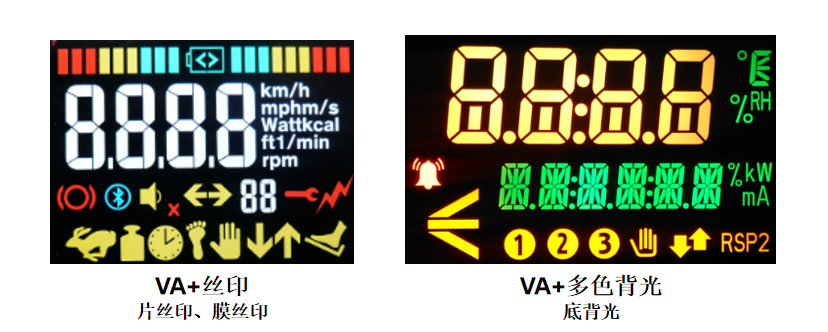

Colorful & Personalized Display: Monochrome displays can also be "colorful." We achieve this through two technical paths:

1.VA + Screen Printing: Screen printing (on the film or glass) is applied to the polarizer of the lcd module, creating fixed-color icons, logos, etc., enhancing product brand recognition and aesthetics.

2.VA + Multi-Color Backlight: By programming the color of the bottom LED backlight, the same screen can switch between different display colors, dynamically conveying diverse status information.

Part Three: Functional Integration – Seamlessly Embedding Touch Interaction into the LCM

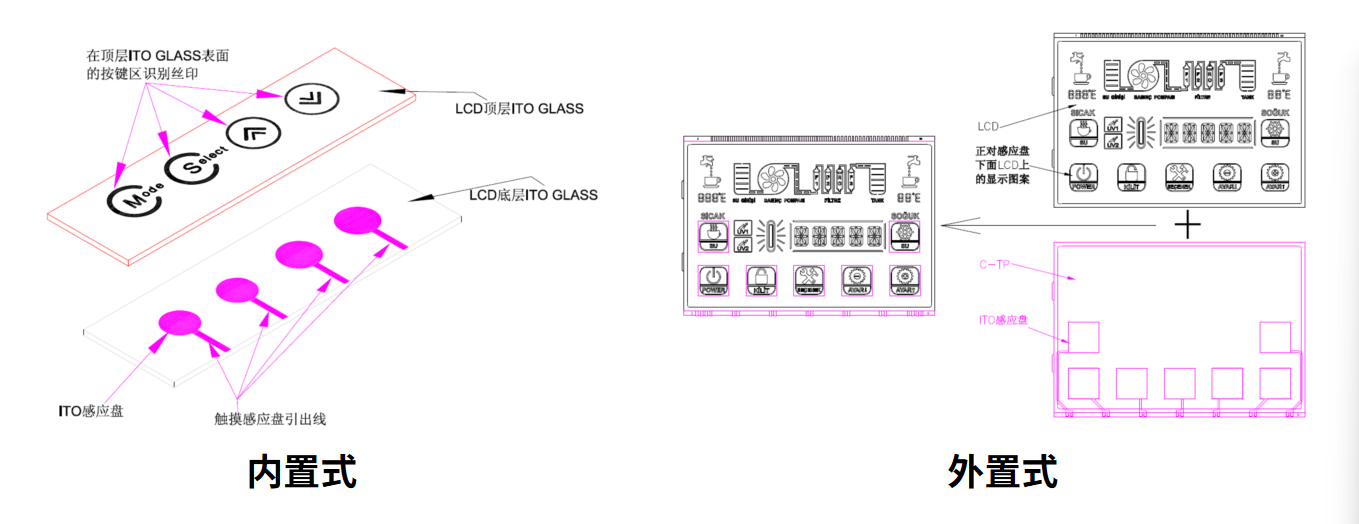

Modern smart devices rely on smooth touch experiences. We deeply integrate touch functionality into the lcd module, offering flexible CTP solutions.

Built-in vs External: Depending on the structural design, you can choose to have the touch sensor directly fabricated on the surface of the lcd screen (On-Cell), or as a separate component attached externally to the module (External). The On-Cell solution helps reduce the overall module thickness, while the External option offers more flexibility for repair and replacement.

Self-Capacitive vs Multi-Touch: For simple button needs, self-capacitive CTP offers fast response and strong anti-interference. For applications requiring complex gestures like sliding and pinching, we provide multi-touch CTP solutions, greatly enriching the HMI dimension.

As an experienced lcd display manufacturer, CNK Electronics' value lies not only in providing standardized lcd module but also in our profound technical expertise, enabling us to collaborate with you on R&D and customize lcd screen details – from structure and display to touch. We believe a successful product stems from precise control over every technical aspect.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a specialized and innovative enterprise specializing in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.