Core Display Driver Debugging Technologies & Operational Standards

2025-06-26

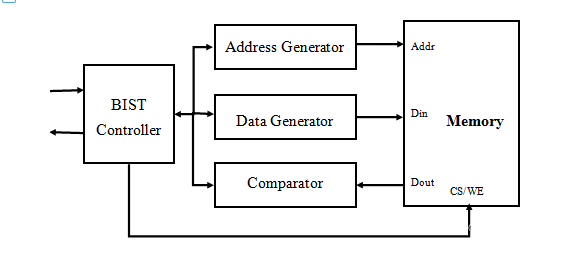

1. Advanced Application of BIST Command

Operating Principle: The driver IC's built-in self-test engine activates upon correct initialization code loading, generating diagnostic patterns (color bars/checkerboards).

Dual Diagnostic Functions:

▶ Fundamental Verification: Absence of output indicates critical errors in initialization timing or register configuration.

▶ Fault Isolation: Normal self-test with external signal failure confirms motherboard signal processing issues.

Extended Applications: Multi-level test modes (controlled via 0x36 register) for grayscale uniformity and color response evaluation.

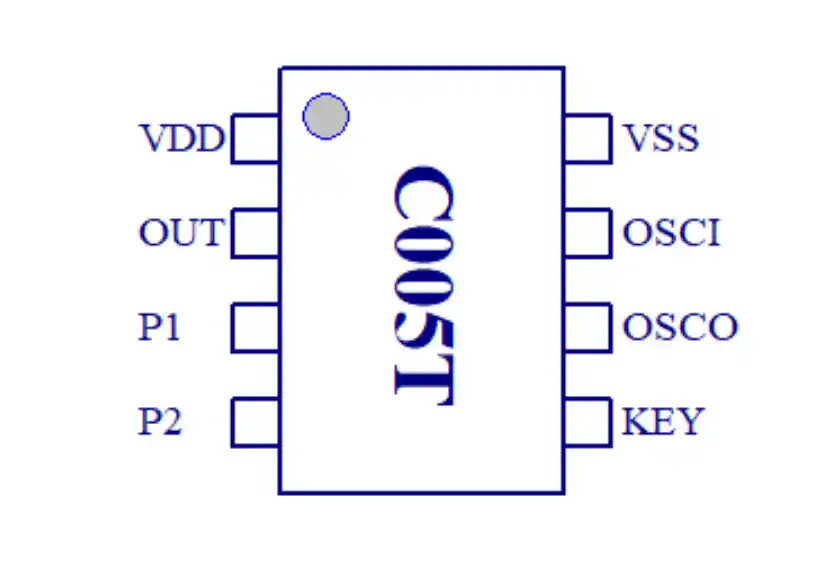

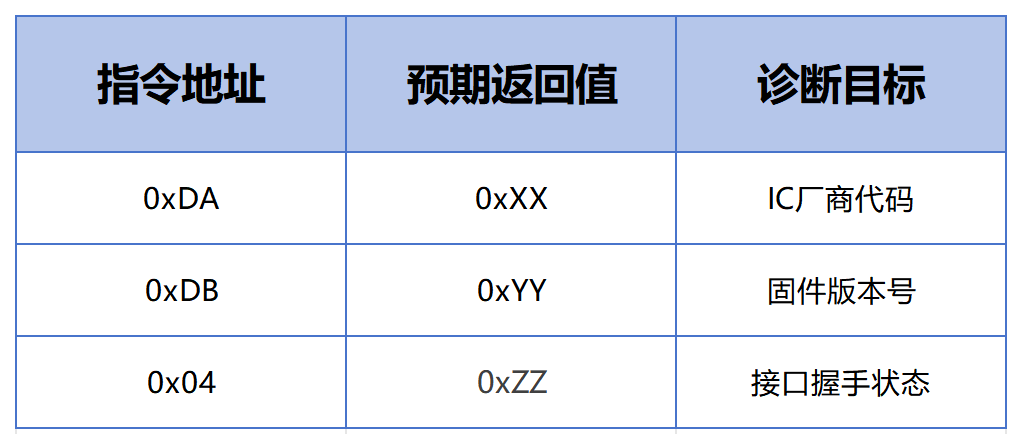

2. Systematic ID Read Command Protocol

Command Matrix:

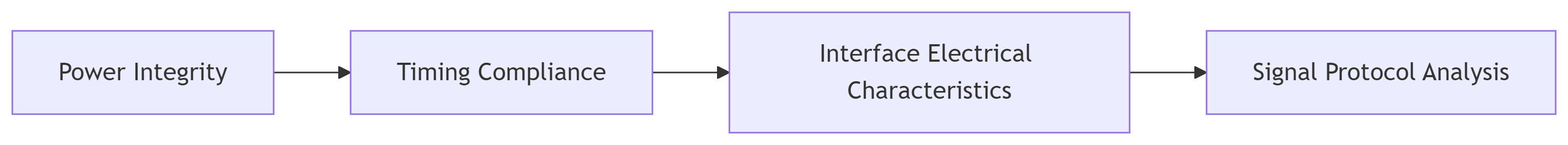

Communication Layer Troubleshooting: Three consecutive read failures require inspection of:

▶ Interface voltage matching (±5% tolerance)

▶ Signal crosstalk (eye diagram opening >0.7 UI)

▶ Power-on timing (Treset_min≥10ms, Tvdds_rise≤100μs)

▶ Ground impedance (<50mΩ)Six-Dimensional Debugging Safety Protocol (Enhanced Golden Rules)Thermal Protection: Initial power-on with current-limited supply (≤200mA), monitored by IR thermal imaging. ΔT>15℃ triggers circuit interruption.

Code Dual-Verification: Official initialization code requires SHA-256 validation with watchdog timer integration.

Secure Code Modification Protocol: Register modifications must pass:

▶ ESD protection test (HBM≥8KV)

▶ 72-hour accelerated aging

▶ Burn-in resistance test (static image 96hrs)

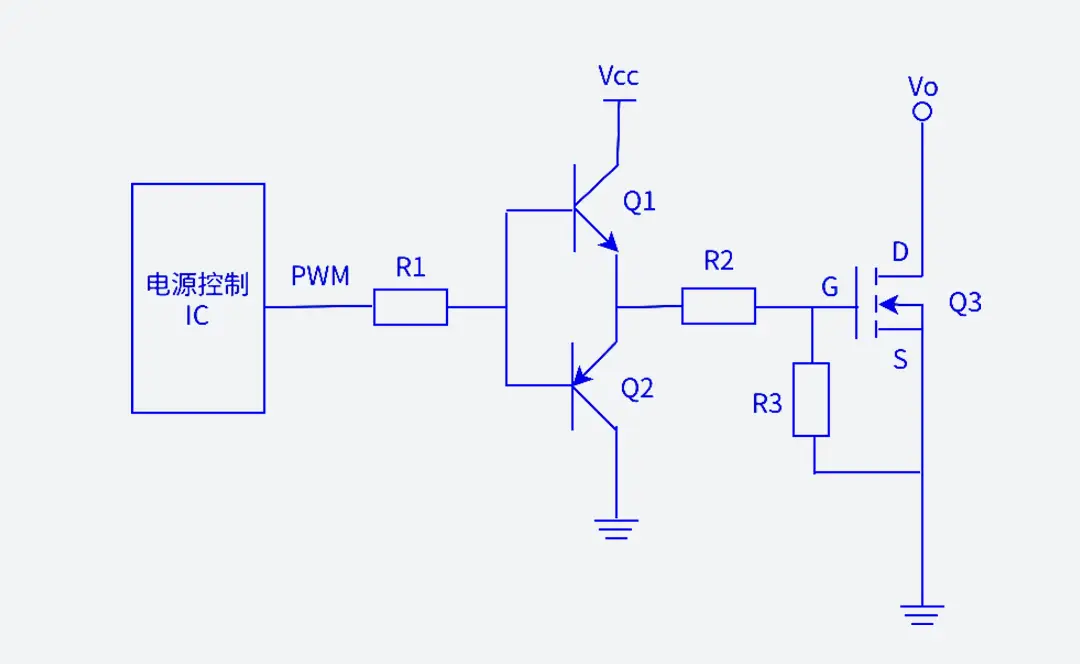

Hardware-First Diagnostic Flow:

Timing Fault Tolerance: Critical timing parameters with ±20% margin; RESET falling edge synchronized with VDDS rising edge (<1μs deviation).

Dynamic Maintenance Algorithms:

▶ Pixel shifting (1-pixel displacement per 2 hours)

▶ Periodic negative image refresh (every 30 minutes)

▶ Adaptive contrast optimization (content-dependent)Industrial-Grade Technical Assurance SystemFull Lifecycle Management: Implements FMEA-driven proactive maintenance from design-in to mass production:

Medical devices: Compliant with IEC 60601-1 leakage current standards

Automotive systems: Certified for -40℃~105℃ thermal cycling

Industrial HMI: Supports 2 million touch-operation endurance

Smart Manufacturing Benchmarks:

▶ Micron-level placement accuracy (±15μm)

▶ In-line AOI inspection (defect capture rate ≥99.2%)

▶ Data traceability system (200+ process parameters per panel)

Critical Warning: Display driver debugging constitutes a precision hardware-software symphony. Unauthorized operations may cause irreversible damage (IC breakdown/electrode carbonization). Implement a hardware sign-off protocol requiring dual approval by senior electronics engineers and display architects.

About CNK

Founded in Shenzhen in 2010, CNK Electronics (CNK in brief) expanded the world leading factory in Longyan, Fujian in 2019. It is a specialized and innovative enterprise specializing in the design, development, production and sales of display products. CNK provides customers with a full range of cost-effective small and medium-sized display modules, solutions, and services with excellent quality worldwide. Oriented in technology and high quality, CNK keeps sustainable development, works to offer customers better and stable services.